|

| Granite Plaza Shopping Center, ~100 Granite Street |

|

| Hancock Park Rehabilitation and Nursing Center |

before heading to dinner in the pretty nicely decorated place.

I had to spend $60 here, and as the prices were pretty cheap here, I had to get a lot of food which got everyone staring at me, and my waiter commenting that he was impressed with how much I was eating. Anyway, on to the dishes.

I got the Roasted Littlenecks (tomatoes, pepperoncini, pancetta, garlic, olive oil),

the Pan Seared Scallops (Scallops wrapped with crispy slab bacon, citrus balsamic syrup),

the Wood Grilled Bruschetta (Spinach, tomato, bacon, apple, roasted garlic),

the Fox and Hound Onion Porter Soup (With dark beer & gruyere crouton),

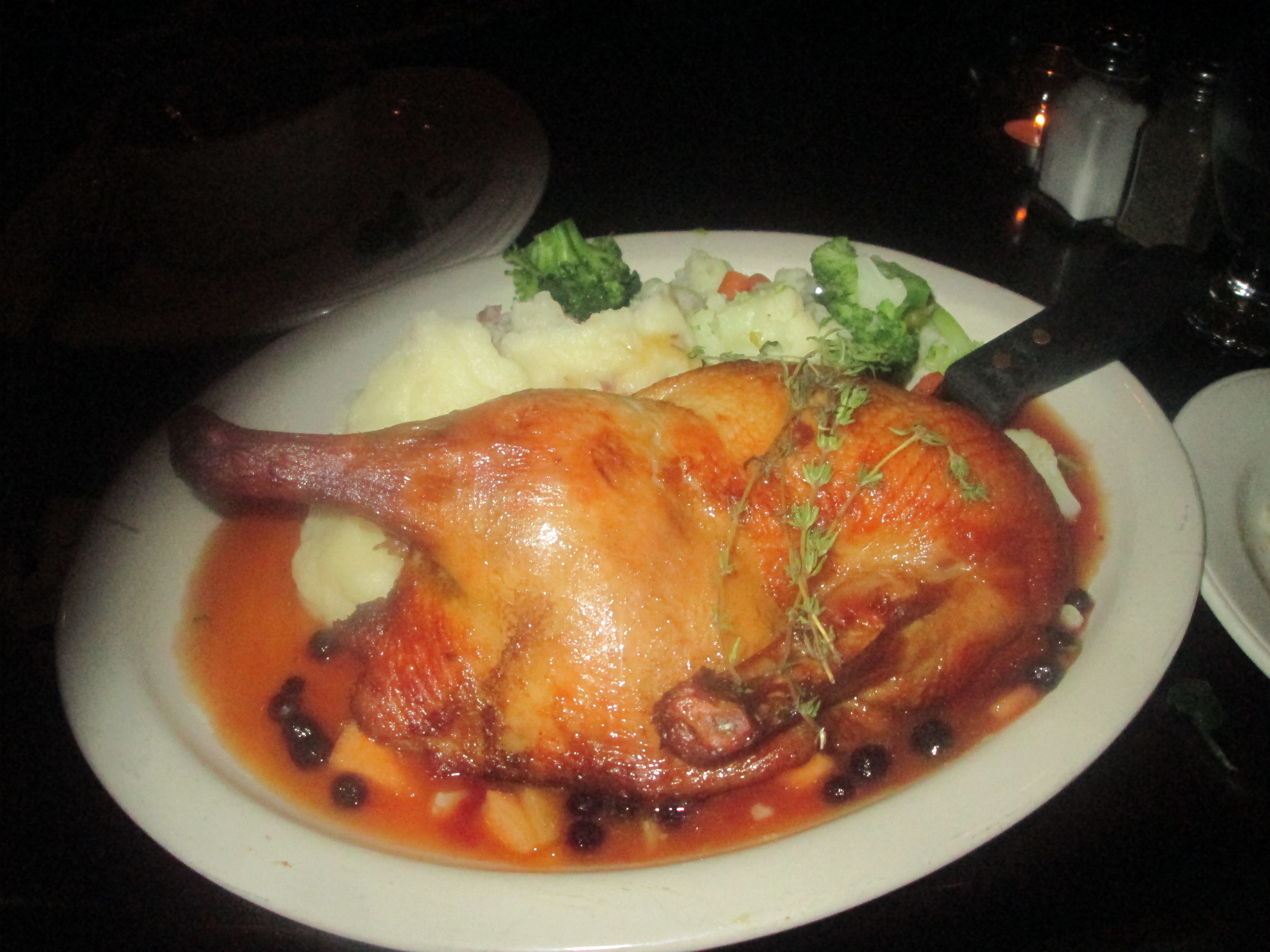

and the Crispy Roast Duck (Half duck, wild blueberry and orange demi, mashed potatoes & vegetable) for my main dish.

Overall, a recommend, although you probably should not order the duck next time.

After dinner, I headed to the soap place, where I was a little early, so I was allowed to walk around and take some pictures of the shop.

I was provided with some interesting equipment to use during the soap making, including a portable stove, goggles, thermometers, spatulas, and a portable blender.

I was then asked to select a scent from a basket of them to use in the soap I was to make, of which I chose Very Vanilla.

We then proceeded to measure the various components and mix them together. For that, I thank my work experience, because I knew how to weight the components accurately, and handle the lye which can be pretty dangerous on physical contact, and the teachers were happy that I made their job so much easier.

We had to mix the stuff in the certain order though. First, adding the lye to water, and not the other way around. Then putting all the oils together and melting them to make a liquid mixture. The scent is by itself, but needs to be weighed as well.

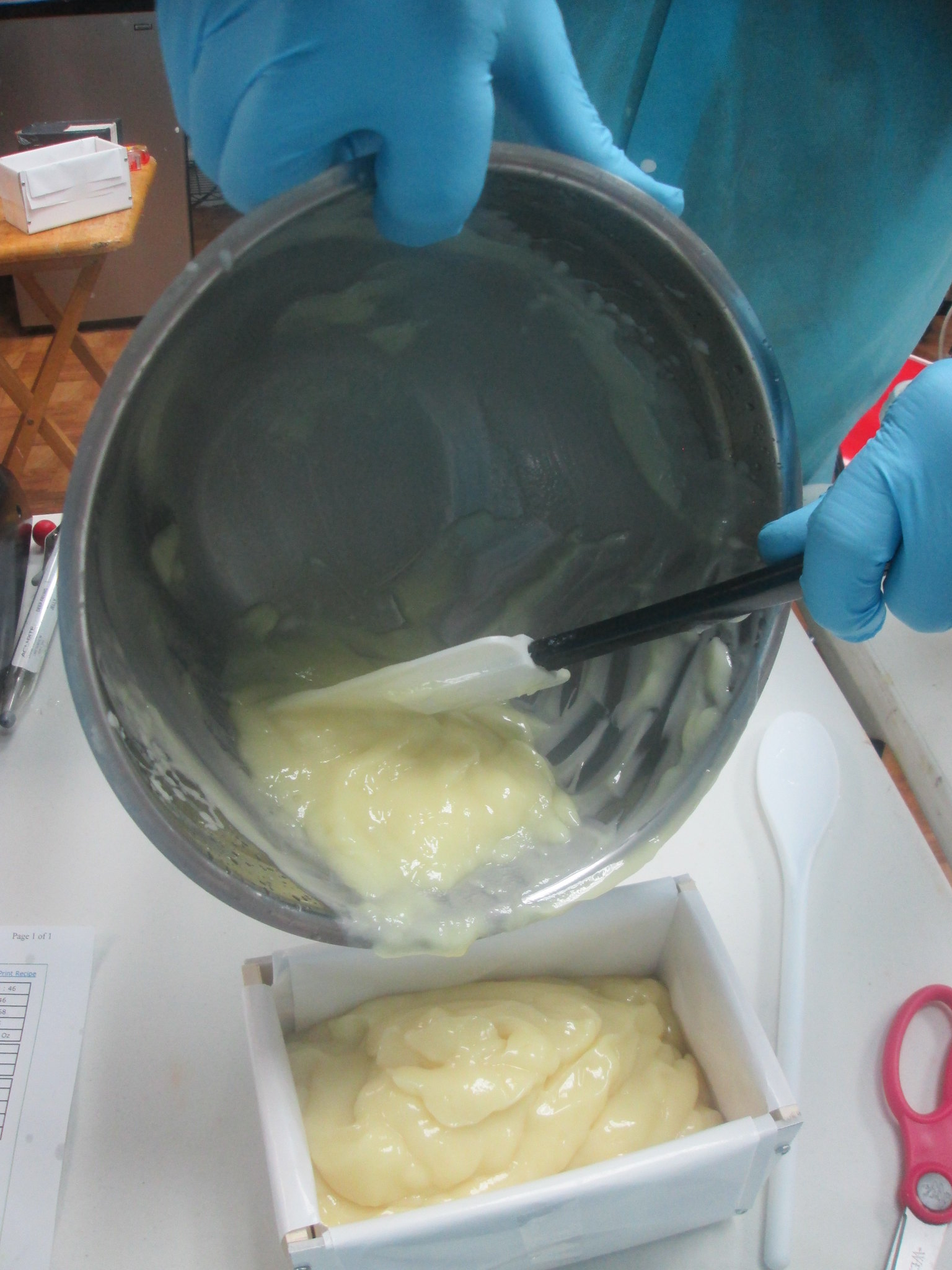

Finally it was time to mix the lye and the oils together. On constant mixing using the blender, which has to be immersed in the mixture to prevent spilling of lye everywhere, a pretty hard thing to do in the least, the mixture first gets a gravy-like texture, after which the scent is added to it.

On further mixing, the mixture starts to get a pudding like feel to it, upon which it is poured into the mold to harden.

No comments:

Post a Comment